Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

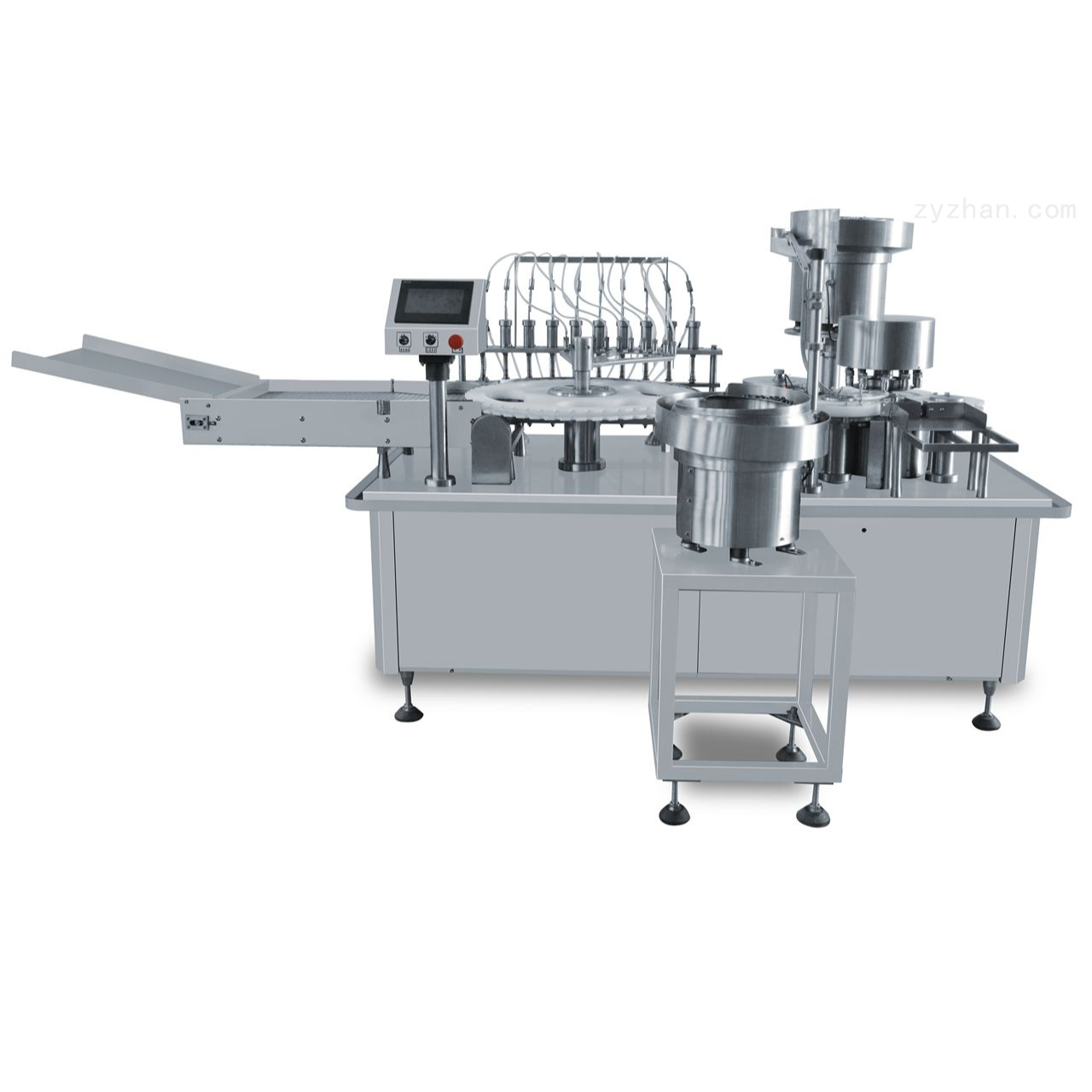

In an era where efficiency and precision are paramount, the manufacturing industry is constantly evolving to meet the demands of a fast-paced world. One such innovation that has revolutionized the way products are packaged is fully automatic encapsulation machinery. This technology has not only streamlined production lines but also raised the bar for quality control and consistency. Whether you're a seasoned manufacturer or a curious entrepreneur, the impact of this machinery on the industry is undeniable and worth exploring.

The world is moving at a breakneck pace, and the manufacturing sector is no exception. The demand for products is higher than ever, and consumers expect them to be of the highest quality. This is where fully automatic encapsulation machinery steps in, offering a solution to the challenges of mass production. By automating the encapsulation process, manufacturers can ensure that every product is packaged to the same exacting standards, reducing the risk of human error and increasing overall efficiency.

One of the most significant advantages of fully automatic encapsulation machinery is the increase in productivity it brings to the table. By removing the need for manual labor in the packaging process, manufacturers can produce more units in less time. This not only meets the high demand for products but also reduces the overall production costs.

Consistency is key in manufacturing, and fully automatic encapsulation machinery delivers just that. Every product that passes through these machines is packaged with the same level of precision, ensuring that there are no variations in quality. This is particularly important for products that require a specific level of protection or have delicate components that need careful handling.

In a world where sustainability is becoming increasingly important, reducing waste is a priority. Fully automatic encapsulation machinery helps in this regard by minimizing the amount of material used in packaging. The machines can be programmed to use just the right amount of material for each product, reducing waste and contributing to a greener manufacturing process.

Safety is always a concern in any manufacturing environment. By automating the encapsulation process, the risk of workplace accidents is significantly reduced. Workers are no longer exposed to the hazards associated with manual packaging, such as repetitive strain injuries or accidents involving machinery.

The versatility of fully automatic encapsulation machinery is another reason why it's gaining popularity. These machines are not limited to a single industry; they can be used in a variety of sectors, including pharmaceuticals, food and beverages, cosmetics, and electronics. This adaptability makes them a valuable investment for any business looking to upgrade its packaging process.

At the heart of fully automatic encapsulation machinery are advanced sensors and controls that ensure each step of the process is executed with precision. These sensors can detect minute variations in the product or packaging material and adjust the machinery accordingly, ensuring that every product is packaged correctly.

One of the most exciting aspects of modern manufacturing is the ability to integrate different systems and machinery. Fully automatic encapsulation machinery can be seamlessly integrated with other production lines, such as filling and labeling machines. This integration allows for a smooth and efficient workflow, further increasing productivity.

In today's data-driven world, the ability to collect and analyze data is crucial. Fully automatic encapsulation machinery comes equipped with systems that can collect data on the packaging process, providing valuable insights into production efficiency, waste reduction, and quality control. This data can be used to make informed decisions and improve the overall manufacturing process.

As technology continues to progress, the future of encapsulation machinery looks promising with the development of more advanced fully automatic systems. These future machines are expected to have improved sensors for better precision. They will also be more adaptable to handle a wider range of products. Additionally, they will have enhanced data collection capabilities for improved quality control.

These advancements are set to transform the packaging industry, ensuring that products are packaged to meet the evolving demands and expectations of consumers.

The impact of fully automatic encapsulation machinery on the manufacturing industry cannot be overstated. It has transformed the way products are packaged, ensuring consistency, reducing waste, and increasing safety. As we look to the future, the potential for further advancements in this technology is exciting, promising even greater efficiency and innovation in the world of manufacturing.

For businesses looking to stay ahead of the curve, investing in fully automatic encapsulation machinery is not just a smart move—it's a necessary one. Embrace the future of manufacturing and experience the benefits of this groundbreaking technology for yourself.