Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

In the ever-evolving world of pharmaceutical manufacturing, technology plays a pivotal role in enhancing efficiency, accuracy, and safety. Among these technological marvels, fully automatic encapsulation machinery ODM (Original Design Manufacturing) stands out as a game-changer, revolutionizing the way we encapsulate medications and supplements. Today, let's delve into the fascinating world of these machines, uncovering their unique features, applications, and the joy they bring to the pharmaceutical industry.

Introduction: The Dawn of Automation

The pharmaceutical sector has witnessed a paradigm shift in recent years, with automation taking center stage. From raw material handling to final product packaging, automation has streamlined processes, reduced human error, and improved product consistency. Fully automatic encapsulation machinery ODM epitomizes this trend, offering customized solutions tailored to specific manufacturing needs.

What is Fully Automatic Encapsulation Machinery ODM?

At its core, fully automatic encapsulation machinery ODM refers to the design, manufacturing, and customization of encapsulation equipment tailored to meet the unique requirements of pharmaceutical and healthcare companies. ODM partners work closely with clients, leveraging their expertise in automation, machinery design, and pharmaceutical processes to deliver turnkey solutions that optimize production workflows.

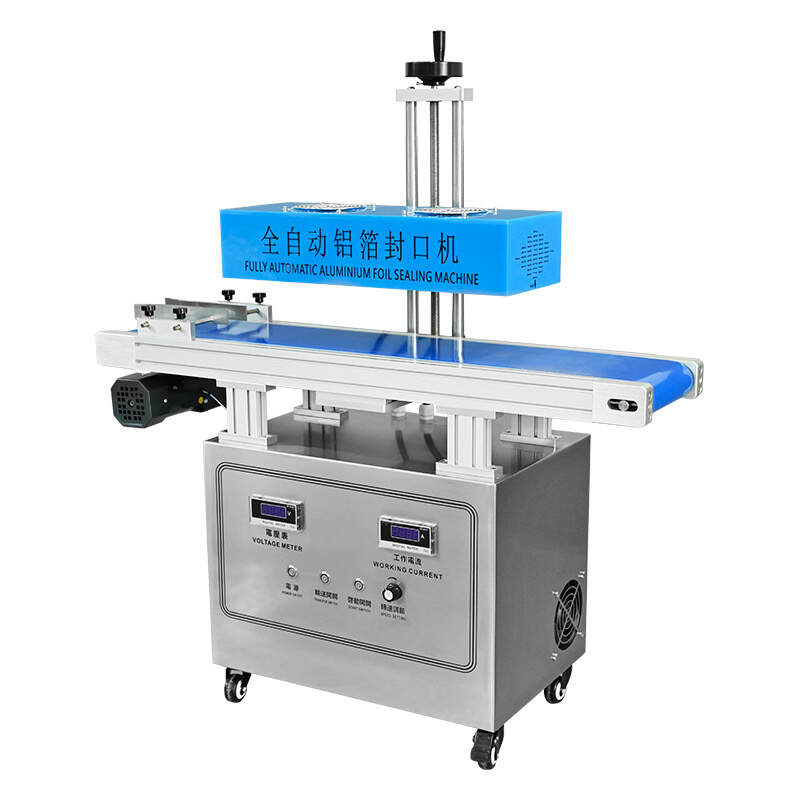

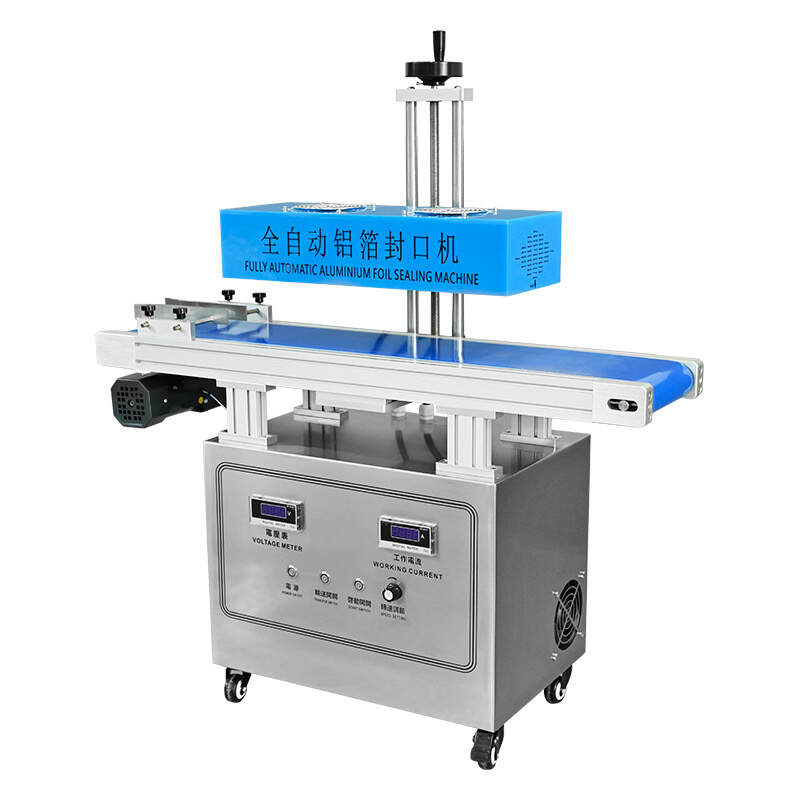

These machines encapsulate various substances, including powders, granules, and pellets, into hard or soft gelatin capsules. They automate the entire process, from feeding the material into the machine, forming the capsules, filling them with the desired substance, sealing, and finally ejecting the finished product. The term "ODM" emphasizes the involvement of the manufacturer in the design phase, ensuring the final product aligns perfectly with the client's specifications and brand standards.

The Magic Behind the Machines

1. Advanced Automation and Control Systems

Fully automatic encapsulation machinery integrates state-of-the-art PLC (Programmable Logic Controller) systems and human-machine interfaces (HMI). These systems enable seamless operation, allowing operators to monitor and control the entire process with ease. Malfunction detection and automatic alarm systems ensure prompt attention to any issues, minimizing downtime and maintaining high productivity levels.

2. Precision and Accuracy

One of the most significant advantages of these machines is their exceptional precision and accuracy. With fine-tuned mechanisms and advanced sensors, they ensure consistent filling weights, minimizing waste and enhancing product quality. Whether it's a powder, granule, or pellet, the encapsulation process is carried out with unparalleled precision, meeting the stringent standards of the pharmaceutical industry.

3. Versatility and Customization

ODM encapsulation machinery offers unparalleled versatility. Manufacturers can customize the machines to accommodate different capsule sizes (ranging from 000# to 5#) and various filling materials. This flexibility ensures that the equipment can be seamlessly integrated into existing production lines, optimizing production capacity and minimizing the need for additional investments.

4. Efficiency and Productivity

Efficiency is the name of the game in pharmaceutical manufacturing, and fully automatic encapsulation machinery ODM delivers on this front. High-speed operations and optimized production cycles ensure maximum throughput, allowing companies to meet market demands swiftly. Moreover, the machines' ability to perform multiple tasks simultaneously (e.g., feeding, filling, sealing, and ejecting) further enhances productivity.

5. Compliance with International Standards

Compliance with international standards is crucial in the pharmaceutical industry. Fully automatic encapsulation machinery ODM ensures that all equipment adheres to stringent regulations such as CE, GMP, and ISO. This compliance not only guarantees product quality but also facilitates market access, enabling companies to expand their reach globally.

Applications and Industries

The applications of fully automatic encapsulation machinery ODM are vast and diverse. From pharmaceutical companies producing vitamins, minerals, and medications to nutraceutical firms creating dietary supplements, these machines play a vital role. They are also used in research and development facilities, where scientists require precise control over encapsulation processes for experimental purposes.

The Joy of Automation

The joy of automation lies in its ability to simplify complex tasks, freeing up human resources for more creative and strategic endeavors. In the case of fully automatic encapsulation machinery ODM, this joy is manifested in several ways:

Conclusion: Embracing the Future of Pharmaceutical Manufacturing

In conclusion, the future of pharmaceutical manufacturing holds immense promise and potential for growth and innovation. As technology continues to advance at an unprecedented pace, the industry is poised to undergo significant transformations that will revolutionize the way drugs are developed, produced, and distributed.

Embracing digitalization, automation, and continuous improvement methodologies is crucial for pharmaceutical manufacturers to stay competitive and ensure patient safety, quality, and efficiency. The integration of advanced technologies such as artificial intelligence, Internet of Things (IoT), and big data analytics is enabling manufacturers to streamline processes, optimize production, and enhance regulatory compliance.

Moreover, the increasing demand for personalized medicine and targeted therapies is driving the need for more agile and flexible manufacturing systems. This shift towards continuous manufacturing and real-time release testing is enabling manufacturers to quickly adapt to changing market demands and accelerate the delivery of new treatments to patients.

Furthermore, the growing awareness of sustainability and environmental concerns is pushing the pharmaceutical industry to adopt greener practices and reduce its carbon footprint. From implementing energy-efficient equipment and processes to developing biodegradable materials, manufacturers are working towards a more sustainable future.

In conclusion, the future of pharmaceutical manufacturing is bright and full of opportunities. By embracing technological advancements, fostering innovation, and prioritizing patient safety and sustainability, manufacturers can create a more efficient, flexible, and environmentally responsible industry that meets the evolving needs of patients worldwide.